Invention Summary:

Immiscible polymer blends (IMPBs) offer versatility in tailoring properties via synergistic combinations of blend components to optimize orthogonal properties more economically than chemical synthesis of a new polymer.

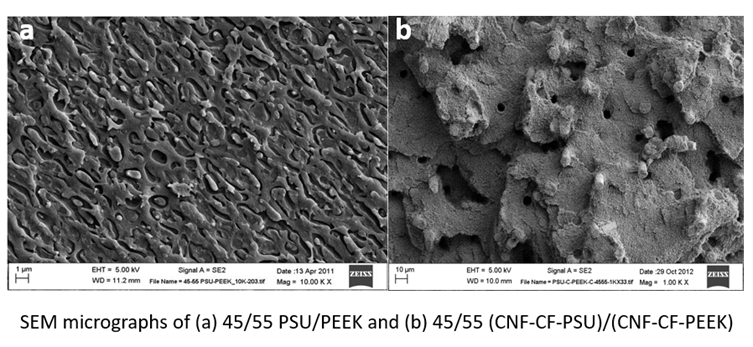

Researchers at Rutgers University have developed a novel processing method to produce high performance carbon fiber-reinforced co-continuous immiscible polymer blends. The blends were formulated from high-performance thermoplastic polymer, polysulfone (PSU), and a semi-crystalline polymer, polyetheretherketone (PEEK), and further reinforced with carbon micro-fibers (CF) and/or carbon nano-fibers (CNF). The reinforced IMPBs approached the specific properties of aluminum and thermoset composites. This invention provides a novel, light-weight composite as an advantageous alternative to traditional materials in the aerospace, automotive, high-end construction and medical device industries.

Advantages:

- Self-alignment of the reinforcing agent during processing

- Amplified effect of the reinforcing agent

- Reduced costs

- A light-weight alternative to traditional materials

Market Applications:

- Aerospace

- Automotive

- Construction

- Medical device

Intellectual Property & Development Status: Patent pending. Available for licensing and/or research collaboration.