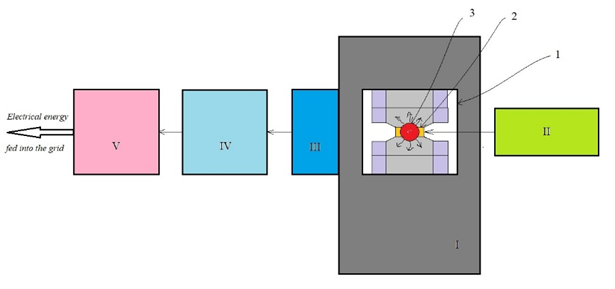

Schematic of a fully integrated high-pressure plasma (HPP) reactor:

I- conventional high pressure/high temperature (HPHT) device,

II-TAP attachment; III-heat exchanger; IV steam turbine;

V-electrical generator; 1-HP unit, 2-container; 3-reaction cell (RC).

Invention Summary:

The feasibility of developing nuclear fusion reactors is often restricted by the requirement of large infrastructure space, high-temperature confinement challenges and the associated cost. It highlights the need to develop small-size reactors that are affordable, and easy to operate.

Rutgers researchers have developed a concept of a bench-top size fusion reactor, based on high pressure/ high temperature (HPHT) design. The design uses a Tungsten-Arc Plasma (TAP) attachment and can withstand up to 10 GPa with WC/Co anvils and 100 GPa pressure with diamond face-shaped WC/Co anvils. The reaction cell consists of a tiny-deuteride-coated tungsten coil embedded in ceramic powder. It is proposed that under HPHT conditions, deuterium ions in proximity may undergo nuclear fusion releasing short bursts of radiative fusion energy.

Market Applications:

- Energy generation in remote locations

- Production of nanocrystalline diamond

- High-pressure applications

Advantages:

- Bench-top size

- TAP operates in a discontinuous mode

- Potential for continuous production of electrical power

- Operates in high pressure unlike Tokamak reactors

Intellectual Property & Development Status: Patent pending. Available for licensing and/or research collaboration. For any business development and other collaborative partnerships, contact: marketingbd@research.rutgers.edu