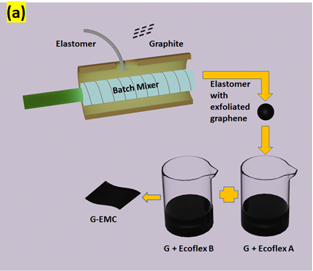

Adding graphite and elastomer to batch mixer for in situ exfoliation

Invention Summary:

It has been known that a material’s electrical, mechanical, and chemical properties can be enhanced with the addition of graphene nanoparticles. Typically, the nanoparticles are created separately from the bulk material and are injected into the polymer and allowed to cure.

Rutgers researchers have developed a novel method to exfoliate the nanoparticles while inside the polymer matrix. This single step procedure is accomplished by adding the bulk graphite to the polymer and shear exfoliating it with a batch mixer. The resultant nanoparticles are distributed throughout the polymer and cured creating the matrix containing the 2D nanoparticles. Removing adding the nanoparticles in a separate step reduces the possibility of contamination and errors in transportation and injection. Team has developed sensor to identify haptic feedback.

Market Applications:

Advantages:

Intellectual Property & Development Status: Provisional patent application filed, patent pending. Available for licensing and/or search collaboration. For any business development and other collaborative partnerships contact marketingbd@research.rutgers.edu