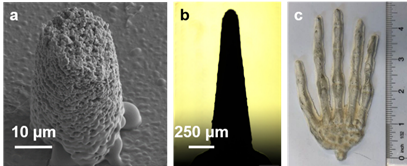

Nanoporous monoliths fabricated at various length scales (a) microscale pillar; (b) mm-scale cone; (c) inch-scale hand cast.

Invention Summary:

A key issue with a majority of the current technologies for creating porous monoliths is that they require high temperature treatments or incur significant materials shrinkage. For many applications, shape is critical and low-temperature substrates or environments are necessary.

Researchers at Rutgers University have developed a new method to synthesize porous resin-particle nanocomposite monoliths. This invention differs from existing mechanisms in that (1) the porogen is separate from the crosslinking phase during the whole reaction and (2) the crosslinking phase possesses a large fraction of nanoparticle fillers. Using commercially available ingredients, the formulated high-viscosity resin can be molded into macro-to-micro shapes and can be cured into a nanoporous material with minimal volume change. Further, the surface chemistry of the final monolith is determined by the nanoparticle component.

Advantages:

- Room temperature processing

- Low shrinkage

- Ideal forming viscosity

- High porosity

- Chemical tunability

- Biocompatibility

Market Applications:

- Water purification

- Aerospace propulsion

- Medical prosthesis

Intellectual Property & Development Status: Patent pending. Available for licensing and/or research collaboration