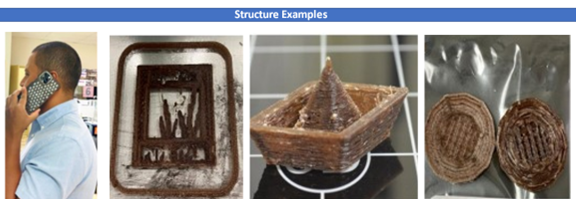

Examples of prints made with Sargassum-loaded filament

Invention Summary:

As a direct effect of ocean warming and nutrient enrichment, tons of brown macroalgae known as sargassum, have been accumulating on shores throughout the Caribbean Sea, Florida, Mexico, and the Bahamas since 2011. These unprecedented annual events have been detrimental not only to marine ecosystems but also to the human health and economy of coastal communities.

Rutgers researchers in collaboration with Ohio University have developed a use for sargassum as a raw material for the fabrication of novel bio-based composite 3D printing materials. The technology has a higher algae biomass content as it can load more than 10% of algae as a plasticizer than other algae-based materials. These sargassum based materials exhibit enhanced material properties and printability compared to commercially available 3D printing materials and biodegrade within 60 days for rapid prototyping.

Market Applications:

- Sustainable 3D printing filament

- Advanced manufacturing additives

- Environmental Remediation

Advantages:

- Loads 10% more algae compared to competitors

- Up to 30% sargassum in PLA filaments

- Biodegrades within 60 days for fast prototyping

- Sargassum is easy to source

Intellectual Property & Development Status:

PCT application filed. Available for licensing and/or search collaboration. For any business development and other collaborative partnerships contact marketingbd@research.rutgers.edu