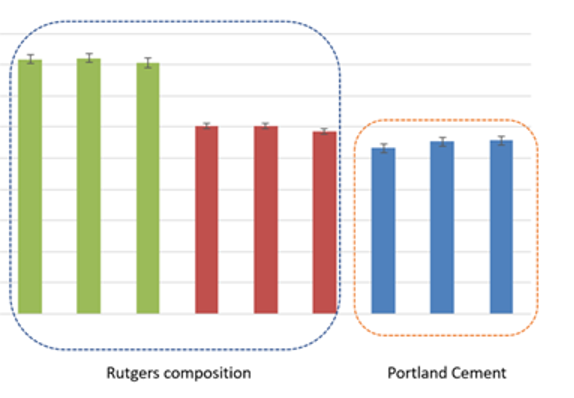

Fig 1. Depicts a comparison of triaxial CU strength for the mixture with Rutgers composition and Portland Cement

Invention Summary:

Management of dredged sediment can be problematic due to the presence of contamination limiting the likely pathways for disposal. The current method to manage these sediments involves stabilization and reuse of dredged material as capping or filling material for landfills and industrial sites. Contaminated dredged sediment is stabilized through the introduction of a binder. Portland cement is the primary binder used because of the interactions with water in the dredged material to form cementitious calcium silicates and aluminates hydrates, which bind dredged material particles together. However, certain limitations associated with the use of Portland cement exist that can adversely impact the stabilization process like hydration reactions and temperature influence.

Rutgers researchers have created a novel solidification material for soil incorporating a calcium silicate-containing composition with a hydration reactivity and a sulfate salt. This solidification material has excellent strength developing properties at low temperature and is capable of solidifying soil to suppress the elution of arsenic from the soil.

Advantages:

- Solidification/Stabilization at low temperatures

- Low cost and made from readily available materials

- Large suppressing effect on the elution of arsenic.

Market Applications:

- Solidification material

- Stabilizer for contaminated sediment

- Impacted urban sediment

Intellectual Property & Development Status:

Patent pending. Available for licensing and/or search collaboration. For any business development and other collaborative partnerships contact marketingbd@research.rutgers.edu