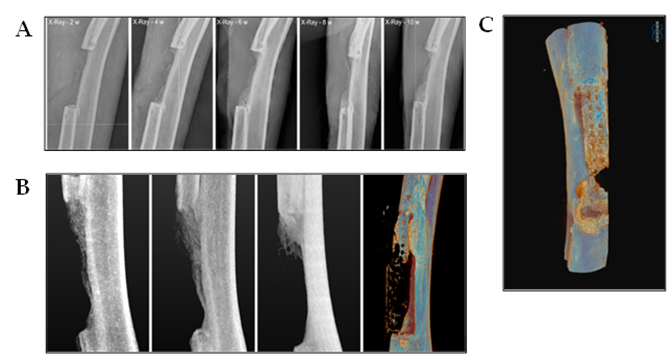

Bi-weekly x-rays (A) showed progressive bone regeneration up to 10 weeks. The reconstructed CT images (B & C) show bone growing into and within the scaffold while the scaffolds maintained their mechanical strength.

Invention Summary:

Over 600,000 bone grafting procedures are performed in the US annually. While bone autografting is the gold standard, it requires additional graft harvesting surgery and the supply of autologous bone is limited. Alternatively, allografting increases the supply of bone grafts but poses risks for disease transmission and immune rejection. Current synthetic grafting materials such as metals are strong but do not degrade or bind to bone, while ceramics are brittle and lack mechanical strength.

Rutgers researchers have developed a 3D-printed bone scaffold designed to promote the regeneration of both bone and its vasculature without the addition of any stem cells and growth factors. When evaluated over 20 weeks in a 15 mm critical-sized radial defect rabbit model, these tissue-engineered scaffolds demonstrated vascularized bone regeneration while maintaining mechanical strength and structural integrity.

Market Applications:

- Scaffolds for bone regeneration and repair

Advantages:

• Load-sharing scaffold that mimics native bone architecture

• Facilitate infiltration of bone marrow, reducing the need to add stem cells

• Sustained mechanical stability in vivo

• Vascularized bone regeneration

Intellectual Property & Development Status: Patent pending. Available for licensing and/or research collaboration. For any business development and other collaborative partnerships, contact: marketingbd@research.rutgers.edu