Invention Summary:

Motivation: Extrusion-based 3D printing of polymer- or polymer-composite parts can realize new applications in metamaterials, batteries, energy, and robotics.

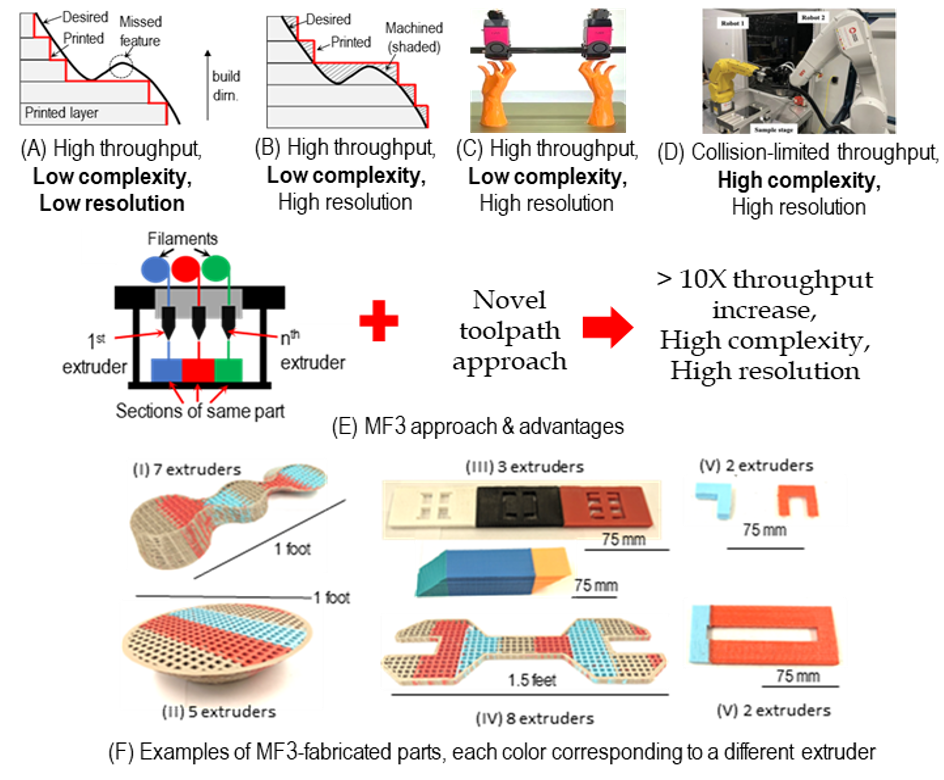

Limitations of existing printing methods: Current extrusion-based 3D printing methods increase throughput by increasing line width and thus cannot resolve complex features (Fig. A). Overprinting and machining prevent creation of complex geometries, like 3D metamaterials, due to limited geometric access while machining (Fig. B). Multiplexed printing with conventional toolpaths is confined to repeating geometries (Fig. C) or is throughput-limited to 3-4 extruders when using one robot arm per extruder due to collision issues (Fig. D). This systemic throughput-complexity-resolution tradeoff limits scalable lab-to-product translation for above applications.

Our Innovation: Rutgers researchers have created MF3 to address this issue. MF3 uses an extruder array (Fig. E) with a fixed inter-extruder distance mounted on a single gantry or robot. A novel toolpath technique prints multiple sections of a part simultaneously, much like an inkjet printer. Unlike similar existing machines each section has a distinct geometry.

Advantages:

MF3 achieves high geometric complexity since non-repeating section geometries enable 3D parts (Fig. F), > 90% build time reduction due to multiplexing, and high feature resolution since each extruder uses a nozzle of small diameter. Using one gantry/robot and fixed inter-extruder distance avoids collisions. Using existing hardware and the ability to retrofit existing FFF machines simplifies the supply chain and reduces adoption cost. The sections have beneficial effects on the part’s mechanical properties.

Market Applications:

Scalable fabrication of 3D printed Metamaterials, Structural batteries, Energy generation, Robotics, and Tooling.

Intellectual Property & Development Status:

PCT application filed. Available for licensing and/or collaboration. For business development and other collaborative partnerships contact marketingbd@research.rutgers.edu