Invention Summary:

Poor solubility is a major obstacle to bringing a drug candidate into the market. Existing methods including micronization, amorphization, spray drying and hot melt extrusion that aim to improve solubility are expensive, difficult to implement, and associated with problems such as instability, limitation in drug loading.

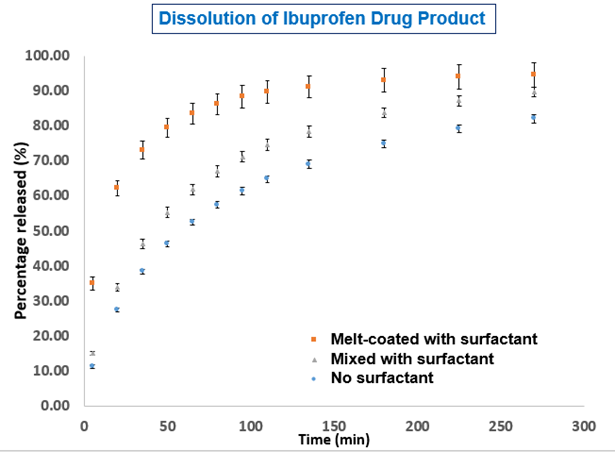

A Rutgers research team led by Prof. Muzzio has developed a novel melt-coating method to enhance the solubility of poorly soluble active pharmaceutical ingredients (APIs). Using continuous heating and shearing, a small amount of low melting point surfactant is coated onto the surface of API particles. In a pilot study, the team has demonstrated significantly improved dissolution of melt-coated ibuprofen. Since this method does not reply on dispersing the APIs in a matrix of other ingredients, it is possible to make tablets, capsules and other oral dosage forms almost entirely composed of the APIs with minimal amount of excipients, thus greatly improving API loading.

Market Applications:

- A platform technology for improving API solubility and increasing API loading

Advantages:

- Easy to implement

- Low cost

- Significantly increased API loading

- Capable of direct integration into continuous pharmaceutical manufacturing systems

Intellectual Property & Development Status: Patent pending. Available for licensing and/or research collaboration.